How CRCA Steel Helps Improve Formability in Sheet Metal Components

Victor Daniel

25 Apr, 2025

5 mins read

30

Victor Daniel

25 Apr, 2025

5 mins read

30

In modern manufacturing, formability is one of the most crucial attributes of sheet metal. Whether it’s automotive panels, electrical enclosures, or precision instruments, manufacturers require materials that can be bent, drawn, stamped, or rolled without cracking or deforming. One material that stands out in this regard is CRCA steel (Cold Rolled Close Annealed). Thanks to its unique properties, CRCA steel plays a key role in improving formability in sheet metal components.

What Is CRCA Steel?

CRCA steel is produced by cold rolling hot rolled pickled steel followed by annealing in a closed atmosphere (usually with inert gases). The cold rolling process increases strength while reducing thickness with precision. The subsequent annealing process softens the steel, refines its grain structure, and removes internal stresses. The result is a sheet metal with excellent surface finish, tighter dimensional tolerance, and improved ductility—ideal traits for forming operations.

Why Formability Matters

Formability refers to a material's ability to undergo plastic deformation without failure during shaping processes like bending, stretching, deep drawing, or stamping. In industries such as automotive and appliance manufacturing, components are often formed into complex shapes. Poor formability can lead to cracking, wrinkling, or dimensional inaccuracies—wasting material and increasing production costs.

How CRCA Steel Enhances Formability

Improved Ductility

The annealing stage in CRCA steel production enhances ductility, making the steel softer and more pliable. This allows it to undergo more severe forming operations without failure. Manufacturers can create intricate shapes and tighter bends without the risk of tearing or cracking.

Uniform Grain Structure

CRCA steel has a refined and uniform grain structure, which contributes to consistent mechanical properties across the sheet. This uniformity ensures predictable behavior during forming processes, resulting in higher precision and fewer defects.

Smooth Surface Finish

The cold rolling process gives CRCA steel a smooth, scale-free surface. This is especially beneficial for applications where surface quality is important, such as in automobile exteriors or decorative panels. A clean surface also reduces friction during forming, extending tool life.

Close Dimensional Tolerances

Tight thickness tolerances in CRCA sheets allow for better control during fabrication. Forming dies and tools can be calibrated more precisely, improving production efficiency and reducing material wastage.

Consistency Across Batches

CRCA steel is known for its consistent chemical composition and mechanical properties across batches. This ensures reliability in mass production, where identical components must be made repeatedly with minimal variation.

Conclusion

CRCA steel’s superior formability, combined with its smooth surface, dimensional accuracy, and uniform properties, makes it an ideal material for sheet metal components. It supports efficient production and minimizes defects in industries that rely heavily on metal forming processes. Whether you're working with automotive parts, home appliances, or precision enclosures, CRCA steel offers the performance and reliability modern manufacturers need.

Written By:

Victor Daniel

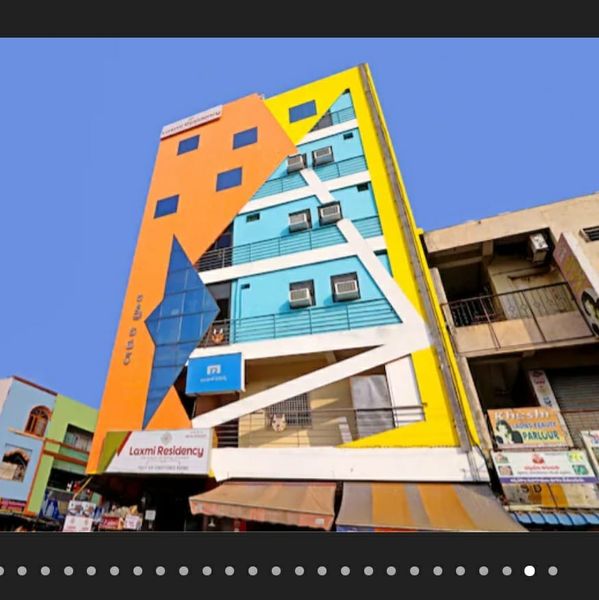

Hotels at your convenience

Now choose your stay according to your preference. From finding a place for your dream destination or a mere weekend getaway to business accommodations or brief stay, we have got you covered. Explore hotels as per your mood.