Technical Ceramics Market: Advanced Materials Powering High-Tech Industries

Tejask Kam

29 Aug, 2025

8 mins read

31

Tejask Kam

29 Aug, 2025

8 mins read

31

Introduction

The global technical ceramics market is experiencing significant growth, driven by technological advancements, industrial innovations, and increasing applications across various sectors. Technical ceramics, also known as advanced ceramics, are engineered materials that exhibit exceptional properties, including high hardness, thermal stability, corrosion resistance, and electrical insulation. These properties make them indispensable in high-performance applications such as electronics, aerospace, automotive, medical devices, and industrial machinery.

Market Overview

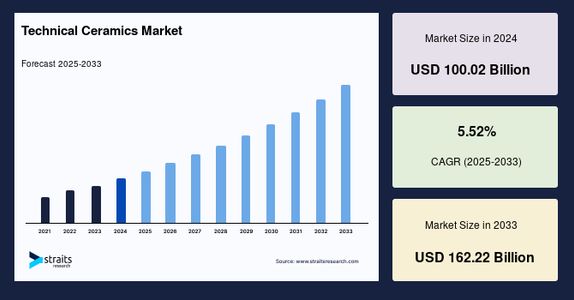

The global technical ceramics market size was valued at USD 100.02 billion in 2024 and is projected to grow from USD 105.54 billion in 2025 to reach USD 162.22 billion by 2033, growing at a CAGR of 5.52% during the forecast period (2025–2033).

The market is segmented based on material type, product type, application, end-user industry, and region, providing a comprehensive view of opportunities and trends.

Key Market Drivers

- Demand in Electronics and Semiconductor Industries

- The proliferation of smart devices, 5G networks, and electric vehicles has increased the need for reliable and miniaturized components. Technical ceramics such as alumina and silicon nitride are used extensively in substrates, insulators, and semiconductor packaging due to their excellent electrical insulation, thermal conductivity, and durability.

- Applications in Aerospace and Defense

- Technical ceramics are employed in aerospace and defense for components such as turbine blades, radomes, and armor systems. Their lightweight, high-strength, and heat-resistant properties make them ideal for mission-critical applications where performance and reliability are non-negotiable.

- Advancements in Additive Manufacturing

- Additive manufacturing, or 3D printing, is revolutionizing the production of technical ceramics. This technology allows the creation of complex, lightweight, and customized ceramic components, reducing material waste and production costs while expanding potential applications.

- Industrial Growth and Automation

- The increasing automation of industrial processes and expansion of heavy machinery operations drive the demand for wear-resistant and durable ceramic components. Technical ceramics enhance efficiency, reduce maintenance, and improve the longevity of equipment.

Market Segmentation

By Material Type:

- Oxide Ceramics: Includes alumina, zirconia, and other oxides, which dominate the market due to their excellent mechanical and thermal properties.

- Non-Oxide Ceramics: Includes silicon carbide, silicon nitride, and boron nitride, valued for their high thermal conductivity, wear resistance, and chemical stability.

By Product Type:

- Monolithic Ceramics: Single-phase materials used in electrical, industrial, and mechanical applications.

- Ceramic Coatings: Applied to surfaces to enhance wear resistance, thermal stability, and corrosion protection.

- Ceramic Matrix Composites: Combine ceramics with other materials to improve toughness, thermal shock resistance, and performance in extreme environments.

By Application:

- Electrical Equipment: Components such as insulators, substrates, and electronic modules.

- Catalyst Supports: Used in chemical and environmental applications to optimize reactions.

- Electronic Devices: Includes capacitors, resistors, and semiconductors requiring high-performance ceramics.

- Wear Parts: Components exposed to friction, abrasion, or high temperatures in industrial and mechanical settings.

- Engine Parts: Turbine blades, seals, and other components in automotive and aerospace engines.

- Filters: Used in environmental and industrial filtration applications.

- Bioceramics: Materials used in medical implants and devices for orthopedic, dental, and cardiovascular applications.

By End-User Industry:

- Electrical & Electronics

- Automotive

- Aerospace & Defense

- Medical

- Industrial Machinery

- Environmental and Filtration Systems

Regional Insights

- Asia-Pacific: The largest market, driven by rapid industrialization, technological advancements, and robust electronics and automotive sectors in countries such as China, Japan, and South Korea.

- North America: Expected to witness strong growth due to high demand from aerospace, defense, and advanced manufacturing industries.

- Europe: Maintains steady growth supported by mature industrial sectors, technological innovation, and environmental regulations.

- Middle East & Africa: Emerging markets with increasing investments in infrastructure, industrial projects, and high-performance technology sectors.

Emerging Trends

- Miniaturization: The demand for smaller, more efficient components in electronics and medical devices is driving the use of advanced ceramics with precise and reliable performance.

- Sustainability: The production of technical ceramics is increasingly incorporating environmentally friendly materials and processes, aligning with global sustainability initiatives.

- Customization: Advanced manufacturing and additive technologies allow for tailored ceramic components, meeting the unique requirements of different industries.

- Integration with Advanced Technologies: Technical ceramics are being integrated into electric vehicles, renewable energy systems, and high-tech industrial equipment, expanding their scope and applications.

Market Outlook

The technical ceramics market is poised for sustained growth due to its indispensable role in high-performance industries. Continuous innovation in materials science, manufacturing processes, and application development is expected to further expand the market. Companies investing in research and development, additive manufacturing, and sustainable practices are likely to gain a competitive advantage as demand for advanced ceramics increases globally.

Conclusion

Technical ceramics are essential for modern technology and industrial applications, offering unmatched durability, precision, and performance under extreme conditions. The global market is benefiting from rapid industrialization, technological advancements, and increasing demand across electronics, aerospace, automotive, medical, and industrial sectors. With continued innovation and regional expansion, the technical ceramics market is set to play a central role in driving the performance, efficiency, and sustainability of future technologies.

Written By:

Tejask Kam

Hotels at your convenience

Now choose your stay according to your preference. From finding a place for your dream destination or a mere weekend getaway to business accommodations or brief stay, we have got you covered. Explore hotels as per your mood.