Cut and Bend Equipment Market: Driving Efficiency in Construction and Manufacturing Industries

Ksh Dbmr

30 May, 2025

7 mins read

25

Ksh Dbmr

30 May, 2025

7 mins read

25

Introduction

Cut and bend equipment plays a crucial role in the construction, manufacturing, and metalworking industries. These machines are designed to precisely cut and shape steel bars, rods, and other metal materials used in building frameworks, infrastructure projects, and industrial applications. The increasing demand for automation, precision, and productivity in metal fabrication processes has led to the growing adoption of advanced cut and bend equipment worldwide.

This article offers an in-depth analysis of the cut and bend equipment market, covering market dynamics, key growth drivers, technological advancements, challenges, regional trends, and future outlook up to 2033.

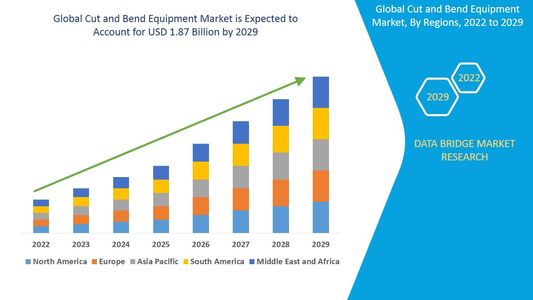

Market Overview

Cut and bend equipment market is essential for processing rebar and structural metal components, ensuring accurate dimensions and shapes needed for construction and manufacturing projects. The global market is valued at approximately USD 1.2 billion in 2024, with a projected growth to nearly USD 2.5 billion by 2033, reflecting a compound annual growth rate (CAGR) of about 8.5%.

Key Market Drivers

- Infrastructure Development

- Rising investments in infrastructure projects globally, including roads, bridges, and commercial buildings, drive demand for cut and bend equipment to support efficient steel reinforcement fabrication.

- Urbanization and Industrialization

- Rapid urban growth and industrial expansion in emerging economies increase construction activities, fueling equipment demand.

- Automation and Technological Advancements

- Adoption of automated cut and bend machines enhances precision, reduces labor costs, and increases operational efficiency, encouraging market growth.

- Labor Shortages and Safety Concerns

- The need to minimize manual labor and improve workplace safety in metal fabrication promotes mechanization via advanced equipment.

- Growing Demand for Precast Concrete Elements

- Precast construction requires precise steel reinforcement, boosting the use of cut and bend machines in production facilities.

Technological Trends

- CNC and Computerized Controls: Integration of computer numerical control improves accuracy, repeatability, and speed in cutting and bending operations.

- Robotics and Automation: Automated loading, cutting, and bending processes reduce human intervention and increase throughput.

- Energy Efficiency: Newer models focus on minimizing energy consumption without compromising performance.

- Compact and Portable Designs: Equipment designed for easy transport and use on-site enhances flexibility for construction projects.

Market Segmentation

- By Equipment Type:

- Rebar Cutting Machines

- Rebar Bending Machines

- Combined Cut and Bend Machines

- By End-User Industry:

- Construction

- Manufacturing

- Automotive

- Infrastructure Development

- By Region:

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East & Africa

Regional Insights

- Asia-Pacific: Expected to be the fastest-growing region due to large-scale infrastructure development in China, India, and Southeast Asia.

- North America: Holds significant market share, driven by advanced construction technologies and stringent building codes.

- Europe: Growth supported by modernization projects and sustainable construction practices.

- Latin America and Middle East & Africa: Emerging markets with growing infrastructure investments and increasing adoption of mechanized equipment.

Challenges

- High Initial Investment Costs: Advanced cut and bend machines require significant capital expenditure, limiting access for small and medium enterprises.

- Maintenance and Technical Expertise: Regular maintenance and skilled operators are essential to ensure optimal performance, which can be challenging in some regions.

- Competition from Manual Labor: In regions with lower labor costs, manual cutting and bending remain preferred, affecting equipment adoption rates.

Future Outlook (2025–2033)

- Increasing focus on integrating IoT and smart technologies for remote monitoring and predictive maintenance.

- Development of eco-friendly and energy-saving models aligning with global sustainability goals.

- Enhanced safety features and operator-friendly interfaces.

- Growth in modular and prefabricated construction boosting demand for precise steel processing equipment.

- Expansion of rental services and leasing options to lower upfront costs and increase equipment accessibility.

Source: https://www.databridgemarketresearch.com/reports/global-cut-and-bend-equipment-market

Conclusion

The cut and bend equipment market is integral to modern construction and manufacturing processes, offering precision, efficiency, and safety improvements. Market growth is propelled by rising infrastructure investments, technological innovations, and a shift toward automation. Overcoming cost and skill-related challenges will be key to broader adoption. With continuous advancements and growing demand worldwide, cut and bend equipment will remain a vital tool in shaping the future of industrial fabrication and construction.

Written By:

Ksh Dbmr

Hotels at your convenience

Now choose your stay according to your preference. From finding a place for your dream destination or a mere weekend getaway to business accommodations or brief stay, we have got you covered. Explore hotels as per your mood.