Industrial Floor Coating Market: Trends, Drivers, and Future Outlook

Tejask Kam

29 Aug, 2025

8 mins read

12

Tejask Kam

29 Aug, 2025

8 mins read

12

Introduction

Industrial floor coatings are specialized protective layers applied to flooring surfaces in various industrial settings, including factories, warehouses, and commercial facilities. These coatings enhance the durability of floors, protect against wear and chemical exposure, and improve safety and aesthetics. The global industrial floor coating market is experiencing significant growth, driven by factors such as industrialization, technological advancements, and increasing emphasis on workplace safety.

Market Overview

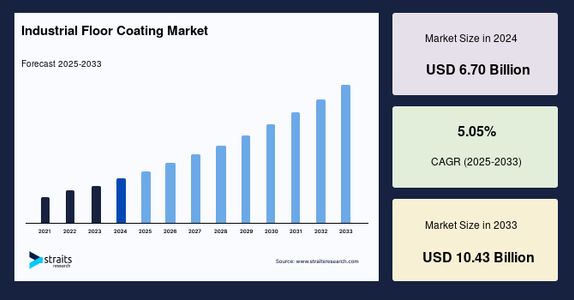

According to Straits Research, the global industrial floor coating market was valued at USD 6.70 billion in 2024 and is projected to grow from USD 7.03 billion in 2025 to USD 10.43 billion by 2033, exhibiting a CAGR of 5.05% during the forecast period (2025–2033).

Market Drivers

1. Industrialization and Infrastructure Development

The rapid pace of industrialization and expansion of manufacturing facilities across various sectors are primary drivers of the market. Additionally, the booming construction sector, especially in commercial and industrial buildings, significantly contributes to market growth

2. Emphasis on Workplace Safety and Cleanliness

There is an increasing focus on workplace safety and cleanliness, leading to higher adoption of coatings with anti-slip and antimicrobial properties. Industries such as food processing, pharmaceuticals, and healthcare, where strict hygiene standards are mandatory, are particularly driving this trend .

3. Technological Advancements

Technological innovations in industrial floor coatings are enhancing performance, safety, and sustainability. Advanced coatings such as self-leveling anti-slip and antimicrobial formulations are gaining traction across industries due to their ability to meet specific functional requirements .

Market Segmentation

By Resin Type

- Epoxy: Dominates the market due to its excellent adhesion, chemical resistance, and durability. Epoxy coatings are widely used in various industries, including manufacturing, warehousing, and food processing .

- Plyurethane: Known for its flexibility and resistance to abrasion, polyurethane coatings are suitable for areas subjected to heavy traffic and mechanical stress.

- Polyaspartic: Offers rapid curing times and UV stability, making it ideal for applications requiring quick turnaround times.

- Acrylic: Provides a cost-effective solution with good resistance to UV degradation and weathering.

- Other Resins: Includes various specialized formulations catering to specific industry needs.

By Flooring Material

- Concrete: The most common substrate for industrial floors, requiring protective coatings to enhance durability and resistance to wear.

- Mortar: Used in areas requiring high compressive strength and resistance to chemical exposure.

- Terrazzo: A decorative flooring option that benefits from protective coatings to maintain its appearance and longevity.

- Others: Includes asphalt and previously coated surfaces requiring maintenance or refurbishment.

By Coating Component

- One-Component: Ready-to-use formulations that require no mixing, offering convenience and ease of application.

- Two-Component: Comprising a resin and a hardener, these coatings offer enhanced performance characteristics.

- Three-Component and Beyond: Specialized formulations providing additional features such as UV resistance or conductive properties.

By Formulation Type

- Water-Based: Environmentally friendly formulations with low VOC content, suitable for indoor applications.

- Solvent-Based: Offers durability and chemical resistance, suitable for demanding industrial environments.

- Powder Coatings: Provide a durable finish without the need for solvents, reducing environmental impact.

By End-User Industry

- Automotive: Requires durable and resistant flooring to withstand heavy traffic and potential chemical spills.

- Chemical and Petrochemical: Demands coatings that can resist aggressive chemicals and high temperatures.

- Food Processing: Necessitates coatings with antimicrobial properties to maintain hygiene standards.

- Pharmaceuticals: Requires coatings that meet stringent cleanliness and safety regulations.

- Construction and Infrastructure: Demands coatings that can withstand heavy machinery and foot traffic.

- Other Industries: Includes sectors such as electronics, logistics, and retail.

Regional Analysis

- Asia-Pacific: The largest market share is held by the Asia-Pacific region, driven by manufacturing hubs in countries like China and India.

- North America: The fastest-growing market, with increasing demand for smart workwear and stringent safety regulations.

- Europe: Steady growth due to established industries and regulatory frameworks.

- Middle East & Africa: Emerging markets with growing industrial sectors.

- Latin America: Developing markets with increasing infrastructure projects.

Challenges

- Cost of Advanced Materials: The integration of smart technologies and high-quality materials increases production costs, potentially limiting affordability for small and medium enterprises.

- Regulatory Compliance: Adhering to diverse safety standards across regions can be complex for multinational companies.

- Supply Chain Disruptions: Global events and geopolitical tensions can disrupt the supply chain, affecting the availability of raw materials and finished products.

Future Outlook

The industrial floor coating market is poised for continued growth, driven by technological advancements, increasing industrial activities, and a focus on safety and branding. Innovations in materials, such as flame-resistant fabrics and moisture-wicking textiles, will enhance the functionality and comfort of workwear. The integration of smart technologies, including wearable sensors and real-time monitoring systems, will further revolutionize the industry, improving safety and operational efficiency.

Conclusion

The global industrial floor coating market is experiencing significant growth, fueled by industrialization, technological advancements, and a heightened focus on safety and branding. As industries evolve, the demand for specialized, functional, and smart workwear will continue to rise, presenting opportunities for innovation and expansion in the sector.

Written By:

Tejask Kam

Hotels at your convenience

Now choose your stay according to your preference. From finding a place for your dream destination or a mere weekend getaway to business accommodations or brief stay, we have got you covered. Explore hotels as per your mood.