Cycloidal Gearbox Design: Principles, Approach & Advantages

MeVirtuoso Virtuoso

26 Sep, 2025

10 mins read

11

MeVirtuoso Virtuoso

26 Sep, 2025

10 mins read

11

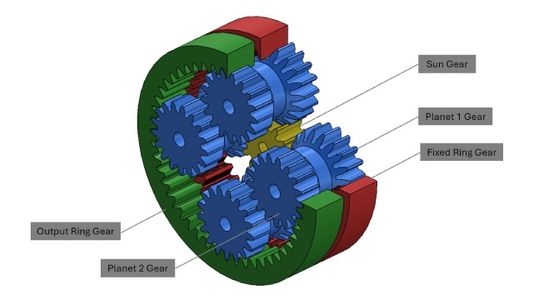

A cycloidal gearbox (or cycloidal drive) is a specialized speed reducer design that offers uniquely high reduction ratios, compactness, and excellent torque transmission—all while minimizing backlash. In contrast to conventional gearsets, cycloidal gearboxes rely on a cam-driven wobble motion of a cycloidal disc interacting with pins or rollers within a ring, which enables precise and durable motion control.

1. Working Principle & Kinematics

At the heart of a cycloidal gearbox is the cycloidal disc, mounted eccentrically on an input shaft. As the input spins, the eccentric motion causes the disc to “wobble†and engage with a set of fixed pins or rollers arranged on a ring gear. The disc’s lobes push against these pins, generating motion that is converted into a slower rotation of the output shaft via holes or pins in the cycloidal disc itself.

One key relationship governs the reduction (gear) ratio:

i=NN−ni = \frac{N}{N - n}i=N−nN​Where:

- NNN = number of pins in the ring

- nnn = number of lobes (or “teethâ€) on the cycloidal disc

The disc typically has one fewer lobe than the number of ring pins, producing the reverse motion and the reduction effect.

Because the motion is distributed over multiple lobes engaging simultaneously, cycloidal drives can transmit high torque with excellent load sharing among contacts.

2. Design Parameters & Geometry

Designing an effective cycloidal gearbox requires thoughtful selection of geometric and mechanical parameters. Below are the core design inputs:

a) Number of Pins and Lobes (N, n)

The choice of NNN and nnn fixes your reduction ratio and also influences stress distribution, pin sizing, and the smoothness of motion.

b) Ring Gear (Pitch Circle) Diameter

Pins are arranged around a base circle. This diameter must match the pitch of lobes and allow suitable spacing between pins.

c) Roller (or Bearing) Radius

Rollers or bearings—positioned between the disc and ring pins—help reduce friction and support radial loads. Their diameter influences contact geometry and clearances.

d) Eccentricity (e)

This is the offset between input shaft center and the cycloidal disc’s pivot. Eccentricity defines how much the disc “wobbles†and influences the engagement amplitude. It must be carefully sized (typically ≤ half the roller diameter) to balance contact forces without risking interference or instability.

e) Hole Size in Disc

Holes in the cycloidal disc allow the output pins to pass through and transmit torque. Their diameter should include allowances for eccentric motion:

dh=dr+2ed_h = d_r + 2edh​=dr​+2ewhere drd_rdr​ is the roller diameter.

f) Profile Construction (Contracted vs. Ordinary Cycloid)

While the “ordinary cycloid†is drawn by rolling a circle on a base circle, designers often use a contracted cycloid (i.e. the drawing point lies inside the rolling circle). This softens the lobes, reduces eccentric unbalance, and leads to improved balance and strength, without altering the reduction ratio.

The practical construction can be visualized using parametric equations:

x(θ),y(θ)x(\theta), y(\theta) x(θ),y(θ)that account for the geometry of lobes, roller radii, and eccentricity. Many modern CAD packages can accept these expressions to generate accurate cycloidal profiles.

3. Single-Stage vs. Multi-Stage Designs

A single-stage cycloidal gearbox delivers large reduction in one compact unit. It is ideal when moderate reduction ratios (e.g. 10× to 100×) suffice, with high efficiency and minimal complexity.

For very high ratios beyond what is practical in one stage, multi-stage cycloidal gearboxes stack successive cycloidal stages. Each stage adds reduction while retaining the low-backlash, high-torque benefits.

In multi-stage designs, careful alignment, balancing, and structural rigidity become more critical, as cumulative errors can amplify.

4. Strength, Deformation & Optimization

Beyond pure geometry, a robust cycloidal gearbox must account for clearance, deformation, and friction in real-world operation. Recent advances propose numerical methods (such as CDFM: Clearance-Deformation-Friction Modeling) to simulate load conditions, optimize tooth clearances, and predict performance under stress.

Key performance aspects to optimize include:

- Contact stresses at the multiple lobes and pin interfaces

- Elastic deformation under high torque load

- Clearance tolerances to avoid jamming or excessive backlash

- Friction losses at interfaces and bearings

Through iterative simulation and finite-element analysis, designers can refine shapes, choose material thicknesses, and size bearings to hit desired life and performance metrics.

5. Advantages & Applications

Cycloidal gearbox design offers several unique benefits that make it highly favorable in high-precision, high-load, and space-constrained systems:

- Near-zero backlash: thanks to the lobed engagement and multiple contact points, positional accuracy is excellent.

- High torque density: a compact cycloidal drive can transmit high torque in a small footprint.

- Load distribution: multiple lobes share load, reducing local stress and improving durability.

- Compactness: high reduction ratios in limited space — unlike long gear trains.

- Rigid, solid parts: unlike strain-wave or harmonic drives, cycloidal designs rely on rigid structures, simplifying fabrication and robustness.

Because of these strengths, cycloidal drives are widely used in robotic joints, precision machine tools, automation equipment, exoskeletons, and aerospace actuation systems.

Moreover, newer research is combining cycloidal drive principles with quasi-direct-drive actuator designs for legged robotics, leveraging learning-based torque estimation to mitigate dynamic nonlinearities.

6. Best Practices & Tips for Designers

To succeed in cycloidal gearbox design:

- Start with the reduction ratio goal: Choose N and n early and derive the rest from that target.

- Balance eccentricity and roller size: Too large eccentricity introduces vibration; too small may lead to slippage.

- Use contracted cycloid profiles to reduce stress concentration and improve balance.

- Simulate deformation and clearances rather than relying solely on ideal geometry.

- Ensure symmetry / multiple disc phases: Often twin discs 180° out of phase reduce unbalanced forces.

- Precision manufacturing is crucial—errors in pin placement or disc geometry reduce performance drastically.

- Design for maintenance and lubrication: smooth rolling contacts must be protected and maintained.

By combining these core principles—geometry, kinematics, load analysis, and practical constraints—you can create a cycloidal gearbox design that is efficient, precise, and robust. When integrated into your internal pages and linked to your service/product offerings on me virtuoso, this content will help inform visitors, boost your SEO relevance for Cycloidal Gearbox Design, and position your site as an expert resource in high-performance mechanical drives.

Written By:

MeVirtuoso Virtuoso

Hotels at your convenience

Now choose your stay according to your preference. From finding a place for your dream destination or a mere weekend getaway to business accommodations or brief stay, we have got you covered. Explore hotels as per your mood.