Why Every Small Manufacturer Needs a Light Fastness Tester

Jazib Khan

21 May, 2025

8 mins read

26

Jazib Khan

21 May, 2025

8 mins read

26

Why Every Small Manufacturer Needs a Light Fastness Tester (Even If You Think You Don’t)

Running a small manufacturing business is no walk in the park. You are juggling operations, customer demands, quality control, and staying competitive all while watching your bottom line. But here is one thing that often gets overlooked and can seriously impact product quality and customer satisfaction: light fastness.

If you are producing anything that sees the light of day fabrics, plastics, paints, or even packaging.How well it holds up against sunlight can make or break your brand reputation. That is where a light fastness tester comes in.

But Firstly What Is Light Fastness?

Light fastness refers to how resistant a material is to fading or degrading when exposed to light, especially sunlight or UV rays. Poor light fastness means your product may look great in the factory, but after a few weeks in real world conditions, it could start fading, yellowing, or deteriorating.

Imagine selling premium outdoor cushions, only to have your customers return them a month later because they look sun-bleached. That is not just bad for business it is a hit to your credibility.

Enter the Light Fastness Tester

This device simulates natural sunlight to test how your product will hold up over time. It puts your materials through controlled exposure to high intensity light, helping you predict how it will perform before it reaches your customers.

For small businesses, especially in industries like textiles, apparel, plastics, automotive interiors, and even cosmetics, a light fastness tester is like an insurance policy for your product quality.

Why Small Business Owners Should Care

You might be thinking, I am m not a big corporation. Do I really need this kind of testing?

Absolutely. Here is why:

1. Reduce Returns and Complaints

Faded colors, cracked plastics, or peeling prints lead to returns. Returns cost money. A tester helps you eliminate weak materials early in the process.

2. Compete With the Big Guys

Large brands have labs full of testing equipment. You can level the playing field by investing in smart tools like a light fastness tester. It is quality control without needing a full-blown R and D department.

3. Protect Your Reputation

One viral review about how your "premium" product faded in the sun can do long-term damage. Testing shows your customers you care about quality and consistency.

4. Compliance and Industry Standards

Many industries especially textiles require certain light fastness ratings for products to be sold internationally. Having the ability to test in house means fewer surprises.

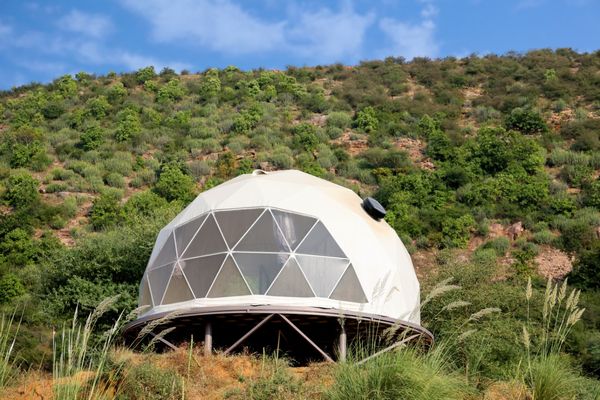

Recommended: Air-Cooled Xenon Arc Tester YG611M

Now, not all light fastness testers are created equal. For small businesses looking for performance, accuracy, and affordability, we highly recommend the Air-Cooled Xenon Arc Tester YG611M.

Here is why this model is a game-changer:

- Air-Cooled Efficiency: No need for complex water systems. Just plug it in and get started.

- Xenon Arc Light Source: Closely replicates natural sunlight, giving you real-world accuracy.

- Easy Operation: Designed with intuitive controls, so you do not need a lab technician to run it.

- Reliable Performance: Built to last with stable output essential for consistent testing.

- Compact Design: Perfect for small labs or even production floors.

Whether you are testing fabrics, plastics, coatings, or dyes, this machine has your back.

How to Use a Light Fastness Tester (Quick Overview)

If you are new to this, do not worry. Using a light fastness tester like the YG611M is surprisingly straightforward:

- Prepare the sample: usually cut to size and conditioned.

- Insert into the chamber: alongside a control standard if needed.

- Set test parameters: such as exposure time and light intensity.

- Run the test:let the machine do its thing.

- Analyze results: check color fading or material degradation visually or with instruments.

No PhD needed. Just a focus on quality.

Final Thoughts: Invest Small, Win Big

In todays market, quality is the differentiator especially for small businesses. A faded product, even if it is just cosmetic, can send the wrong message. Customers expect durability and performance, even in the little details.

A light fastness tester is not just a lab tool. It is a competitive advantage. It is peace of mind. And it is one of the smartest investments you can make if your product is exposed to light.

So whether you are already battling sun fade complaints or just thinking ahead, consider stepping up your game with a tool like the YG611M.

Written By:

Jazib Khan

Hotels at your convenience

Now choose your stay according to your preference. From finding a place for your dream destination or a mere weekend getaway to business accommodations or brief stay, we have got you covered. Explore hotels as per your mood.